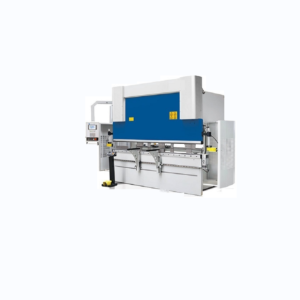

Press brakes are used to bend and fold metal by pressing it into a die. These presses are designed for both specialized sheet metal work and continuous production applications. They can handle tough industrial production jobs from single-cycle operations to automated cell components.

CNC hydraulic press brakes are a large cold forming machine designed for precision metal forming processes. It bends sheet metals to form desired profiles. Some models can provide up to 4,000 tons of bending force during operation. A typical press has a width ranging from 4 to 30 feet.

The essential parts in a CNC hydraulic press brake include a hydraulic unit, a control panel, a controller with an automatic feeder, a bolster plate, a ram, and the frame.